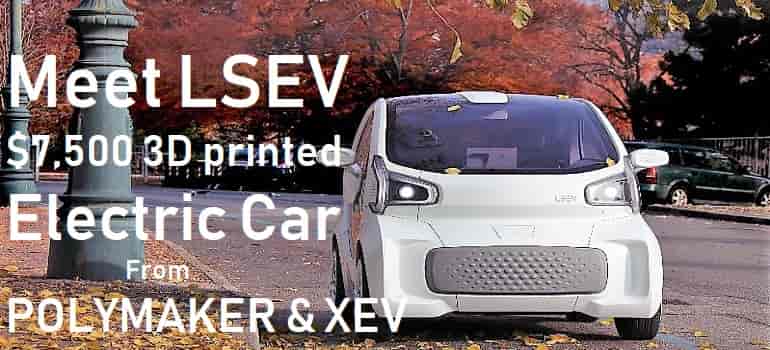

An Italy-based electric car company XEV and 3D printing material company Polymaker recently at China 3D-Printing Cultural Museum in Shanghai launched first mass-producible 3D-printed electric car named as LSEV.

3D printed electric car-LSEV could be the milestone product in the adoption of 3D printing into mainstream production said the company in a statement.

“XEV is the first real mass production project using 3D printing. By saying real, I mean there are also lots of other companies using 3D printing for production. But nothing can really compare with XEV in terms of the size, the scale, and the intensity,” said Dr. Luo Xiaofan, the co-founder and CEO of Polymaker.

XEV CEO, Stanley said that “after the research and investigation of the global auto market, they decided to design a small electric vehicle that can achieve C2M (Customer-to-Manufacturer) manufacturing which is stated as a main goal of the Industry 4.0 strategy.”

To fulfill this target, it requires mass customization production, fast and cost-effective R&D, and the ability to produce lighter-weight parts that could lead to greater fuel efficiency. (Read ClipperCreek launches 64 Amp EVSE for Home and Commercial Use)

“And then, 3D printing technology becomes the only way to realize it”, said Stanley.

The company notes that surely there are many difficulties when utilizing 3D printing technology in auto volume production, Polymaker was chosen as the strategic partner and successfully helped XEV to solve them, not only with material solutions, but also post-processing options in-line with the automotive industry.

“Without Polymaker, we couldn’t make this happen. We really like our interactions with Polymaker, this can be called as know-how combination. Without this kind of interaction, we also couldn’t find the solution we have today. So, we really appreciate what Polymaker do and create for us, we are like brothers, not just strategic partners.” said, Stanley.

XEV has decreased the plastic parts and number of components in a car from more than 2,000 to 57, and the finished LSEV weighs only 450 kilograms, much lower than similar sized vehicles usually weighing between 1 and 1.2 metric tons. (Read Global Electric Vehicles Battery Market to Reach $93.94 Billion by 2026: BIS Research)

Apart from the chassis, seats and glass, all the visible parts of the car are made by Polymaker materials through 3D printing. This switch of production leads to more than 70 percent reduction of the investment cost in comparison with a traditional production system.

Conventionally the R&D process of a car model takes about 3-5 years, but it only takes XEV 3-12 months to finish a new design. (Read There is need for a policy to promote electric vehicles in India: Niti Aayog)

Polymaker have also come up with solutions to help with surface treatments and color. These solutions are enormously helpful in customized production and 3D printing volume production.

XEV has already received 7000 orders from Europe even before mass production commences. XEV plans to start production in the second quarter of 2019.

This strategic partnership between XEV and Polymaker leads to a revolutionary change in automotive manufacturing. It is possible that similar changes, related with 3D printing technology, will happen to every aspect of manufacturing very soon. As Polymaker proves that the 3D printing materials they provide are ready for not only end-use parts but also mass production of finished products.