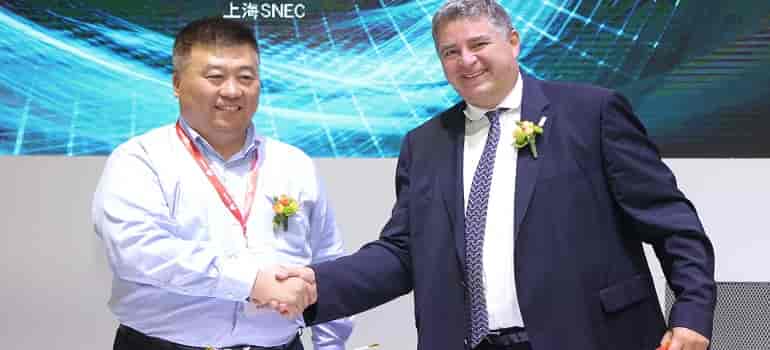

Heraeus Photovoltaics announced comprehensive strategic partnership agreement with Jiangsu Zhongyu Photovoltaic Technology Co., Ltd. (“Solarspace”) at 2018 SNEC International Photovoltaic Power Generation and Smart Energy Exhibition & Conference.

Heraeus Photovoltaics announced comprehensive strategic partnership agreement with Jiangsu Zhongyu Photovoltaic Technology Co., Ltd. (“Solarspace”) at 2018 SNEC International Photovoltaic Power Generation and Smart Energy Exhibition & Conference.

The agreement covers not only Solarspace’s conventional additive texturing (on DWC wafers) and MCCE (on black silicon) processes, but also its forthcoming high-efficiency technologies such as monocrystalline passivated emitter and rear contact (PERC), selective emitter (SE), and heterojunction (HIT) solar cells.

Both the companies also agreed to open a key laboratory together to develop new materials and processes. Going forward, Heraeus will provide highly efficient metallization pastes and a full range of optimized solutions to improve efficiency while addressing costs.

“The sound and sustainable growth of Solarspace from 2010 to 2018 is attributed to our principle of putting quality first. Right from the beginning, we have maintained a close cooperation with Heraeus in the development of products, applications and technology roadmaps. Heraeus has always been with us at many of our key growth stages: for example, it offered 9641B-1188 paste to help us move from conventional screens to high-mesh 440 screens in the very beginning to achieve a 0.05% efficiency gain, and customized 9651D-140 paste for us in response to higher challenges for printability and adhesion on the DWC wafers to meet the requirements of our production lines,” said Liu Guyan, general manager of Solarspace, at the signing ceremony. “The next two years will see Solarspace growing rapidly. With the strong support of Heraeus, we are fully confident of our follow-up development plans.”

Zhang Weiming, Chief Technology Officer and Executive Vice President of Heraeus Photovoltaics, said, “The long-lasting cooperation between Heraeus and Solarspace has been good for our respective growth. Based on our in-depth and open cooperation, we have removed numerous technical barriers and witnessed the booming of Solarspace. We are now well prepared to help Solarspace grow sustainably by meeting its requirements for improved efficiency in a timely way.”

The partnership can be traced back to 2010 upon the inception of Solarspace. From the earliest single printing on slurry-cut silicon wafers to the current single/dual printing on addictive DWC wafers and black silicon, Heraeus has been involved in each technical upgrade of Solarspace, with generations of metallization pastes, including 9610X, 9621X, 9631X, 9641X and 9651X.

Heraeus also provides long-term in-plant services and customized products, and carries out regular exchanges on R&D, promptly troubleshooting the problems with production lines and products for Solarspace, and offering individual solutions to improve cell efficiency.

In early 2018, Solarspace launched a plan called “10GW in 2020” to expand its annual capacity from the current 2GW to 10GW within the next two years. In the same timeframe, high-efficiency technologies such as mono PERC, SE and HIT will be introduced. As for this new development plan, Heraeus will collaborate with Solarspace in the next-generation process upgrade, reduce costs and improve efficiency in monocrystalline technology all the while mapping out a plan to tap into the applications of low temperature pastes. Numerous Heraeus patents in pastes will also enable Solarspace to provide industry-leading customers with the latest technical solutions.