Metastable Materials, a deep-tech recycling company that specializes in lithium-ion batteries, has announced seed funding led by Surge, Sequoia Capital India, and Southeast Asia’s rapid scale-up program.

The funding round also included participation from deep-tech VC Speciale Invest, Theia Ventures, and other angels.

The startup aims to revolutionize the industry for Li-ion battery recycling, which is currently valued at US$4.6 billion, by developing a chemical-free Integrated Carbothermal Reduction™ process for recycling and extracting valuable materials from Li-ion batteries.

Metastable’s process significantly reduces capital and operational expenditure in comparison to conventional battery recycling practices and boasts a recovery rate of over 90%.

The startup is also developing storage and packaging solutions to safely move used batteries from consumers to recycling facilities.

To support its growing operations, the new funding will be used for recruitment to support Metastable’s manufacturing and industrial engineering functions, as well as managing its supply chain and day-to-day operations.

The startup recently opened a 21,000 sq ft urban mining facility located on the outskirts of Bengaluru, which can process 1,500 tonnes of material annually, accounting for up to 6% of India’s recycling demand for Li-ion batteries.

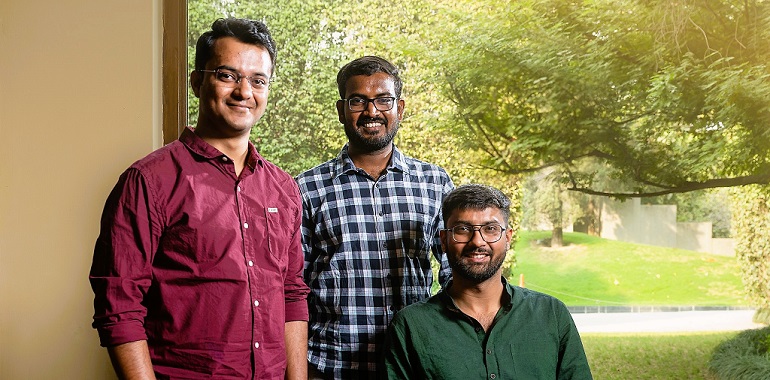

Metastable Materials was founded in October 2021 by Manikumar Uppala, Saurav Goyal, and Shubham Vishvakarma, who met while studying at the Indian Institute of Technology Roorkee.

The startup’s founders bring expertise in industrial engineering, process engineering, and supply chain planning, making them well-positioned to revolutionize the Li-ion battery recycling industry.

Metastable’s innovative, scalable, and greener process for rare material extraction from electronic waste could play a crucial role in the climate tech, decarbonization, and circular economy agenda for India and the world.

As demand for Li-ion batteries continues to rise rapidly worldwide, Metastable’s breakthrough technology could prove to be an essential solution for handling end-of-life Li-ion batteries sustainably, cost-efficiently, and environmentally friendly.