The Unseen Pillar of India’s Solar Ambitions: Why Fixing the Mounting Structure Supply Chain is Critical for a Sustainable Green Future

India’s solar energy sector is undergoing a historic expansion. With over 70 GW already installed and ambitious targets pushing for 280 GW of solar capacity by 2030, the country is firmly on the path to a greener future. But while solar modules, inverters, and financing solutions are drawing attention, there is a silent, often overlooked component that holds everything together solar mounting structures.

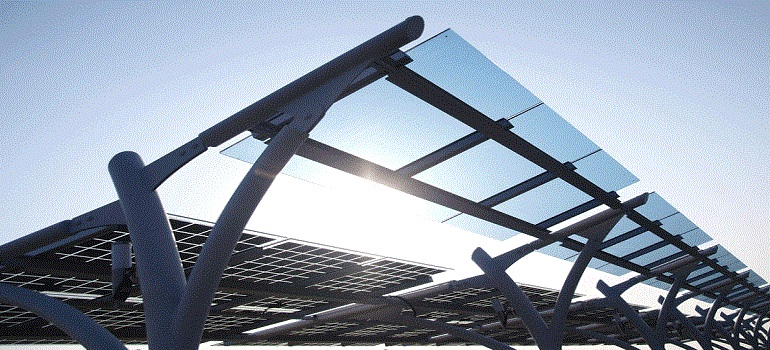

These structures may seem like a basic element, but they are the physical backbone of every solar project. Whether it’s a ground-mounted utility-scale installation or a rooftop system, the quality and reliability of the mounting structure determine the lifespan, efficiency, and safety of the solar array. Without a robust and timely supply of these structures, the very foundation of our solar ambitions is at risk.

Mounting the challenge: where the gaps lie

Today, developers and EPC contractors across the country are increasingly facing delays in procuring mounting structures. The issue is not simply about availability, but about standardization, quality control, and speed. Many suppliers operate at a regional scale, lacking the capacity to deliver at the pace and scale needed for India’s growing pipeline of solar parks and open-access projects.

Even when material is available, lack of uniform standards often leads to structural mismatches, costly redesigns, or on-site modifications. These inefficiencies add both time and cost to projects that are already working with thin margins. The result is a fragile supply chain that can buckle under pressure as project sizes increase.

Steel volatility and manufacturing fragmentation

The core raw material steel adds another layer of complexity. With price fluctuations, supply-chain constraints, and regional disparities in quality and availability, manufacturers of solar mounting structures face challenges in planning and pricing. Many operate without long-term steel procurement strategies, leaving them vulnerable to market shocks.

Additionally, the structure manufacturing ecosystem is highly fragmented. Small to mid-sized fabricators dominate the landscape, often with limited automation, testing, or R&D support. The absence of a national standard or compliance regime further amplifies variability in quality. When project developers are forced to coordinate between multiple vendors, the process becomes error-prone and inefficient.

Time for aggregation and a new sourcing model

The solution lies in bringing structure to the structure business. The industry needs a well-organized, aggregated approach to sourcing. Just as solar modules have benefitted from economies of scale through central procurement and long-term contracts, mounting structures too require a similar mindset shift. Aggregators who can consolidate demand, assure quality, and work with a pan-India supplier network can play a vital role here.

Such a platform-based approach will also allow for better forecasting, planned steel sourcing, and optimized logistics driving down costs while ensuring timely delivery. This is especially critical for developers working on tight construction schedules tied to PPA obligations.

Standardization is non-negotiable

Alongside aggregation, the sector must embrace standardization. Pre-approved structural designs suited to different geographies and wind load conditions can drastically reduce lead times and eliminate the guesswork from the process. These templates should be vetted by independent engineering bodies and adopted across EPC contracts.

What’s missing is not technology, but coordination. India has the design capability, material resources, and engineering talent to build the most resilient solar projects in the world. But unless we standardize what’s beneath the panels, we risk undermining the entire solar value chain.

Looking ahead: building a stronger solar base

As India races to add gigawatts of solar power, we must pay attention to every link in the chain. Mounting structures may not make headlines, but they determine project longevity and safety. It’s time for policymakers, developers, EPCs, and steel suppliers to treat structure sourcing not as an afterthought, but as a strategic priority.

Fixing the mounting structure supply chain isn’t just a logistical need it’s a national imperative. If India wants its solar boom to be sustainable, it must first reinforce its backbone.

Author

Vedant Goel, Director, Enlight Metals,